Top 5 Steam Pressure Reducing Valve Failure Symptoms (Spirax Sarco 25 Series PRVs)

Our Comprehensive Guide to Troubleshooting Spirax Sarco P25 Series Pressure Reducing Valves

Utilizing Steam in your plant is very cost efficient, however if the parts processing the steam aren’t operating to their optimal capacity, you could be losing money. But how do you know which products are causing an issue?

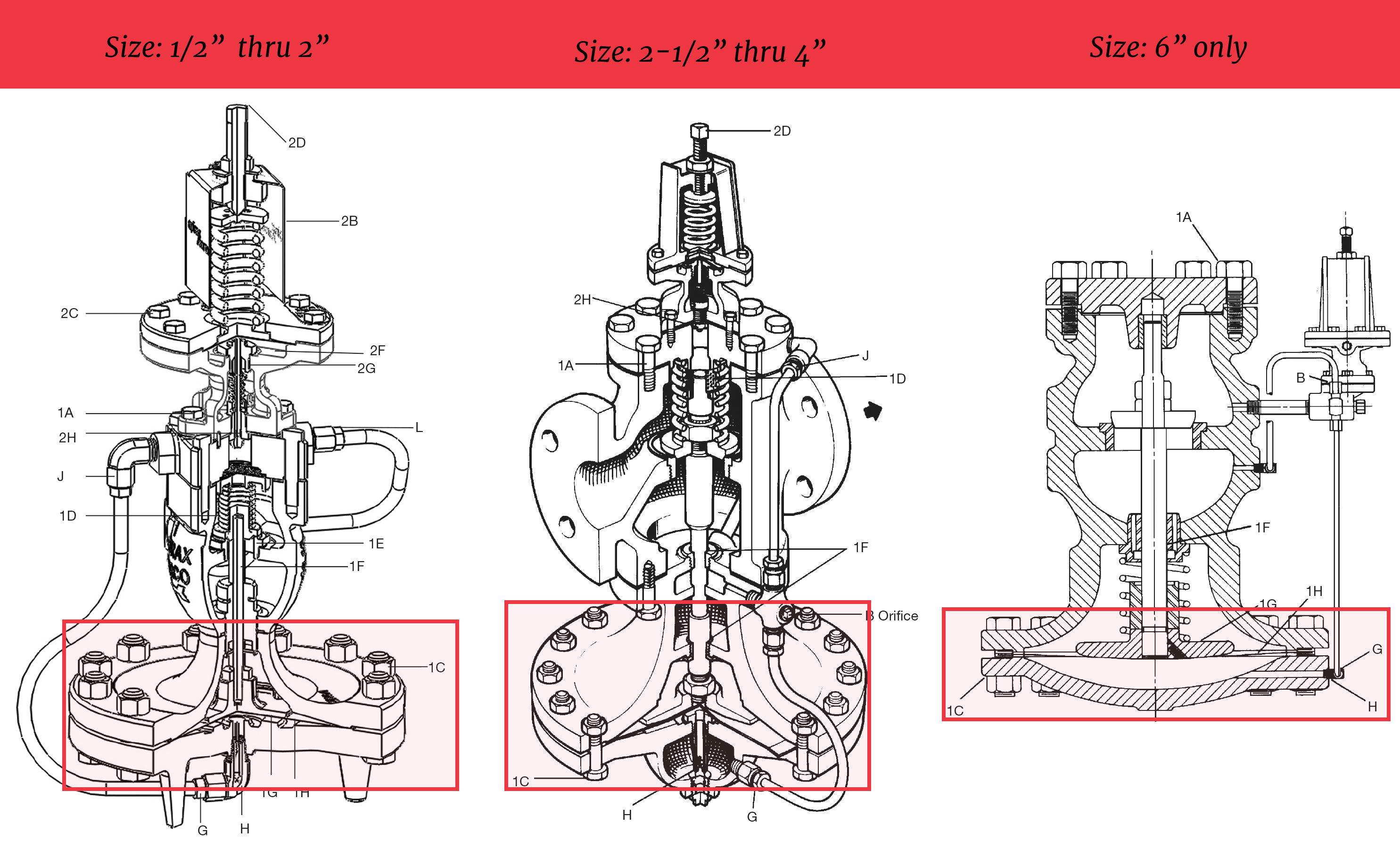

If you have a Spirax Sarco 25P Series Pressure Reducing Valve, here we will guide you through troubleshooting the five most common failure systems, which can be found in Spirax Sarco Installation and Maintenance Instructions for their Type 25P & 25PA Pressure Reducing Valves.

Steam Pressure Reducing Valve Failure Symptom 1: Controlled pressure over-shoots under normal load conditions.

This could mean something is preventing the value from shutting tightly during normal operating conditions. There are three main causes for your pressure reducing valve to fail by the controlled pressure over-shooting under normal load conditions:

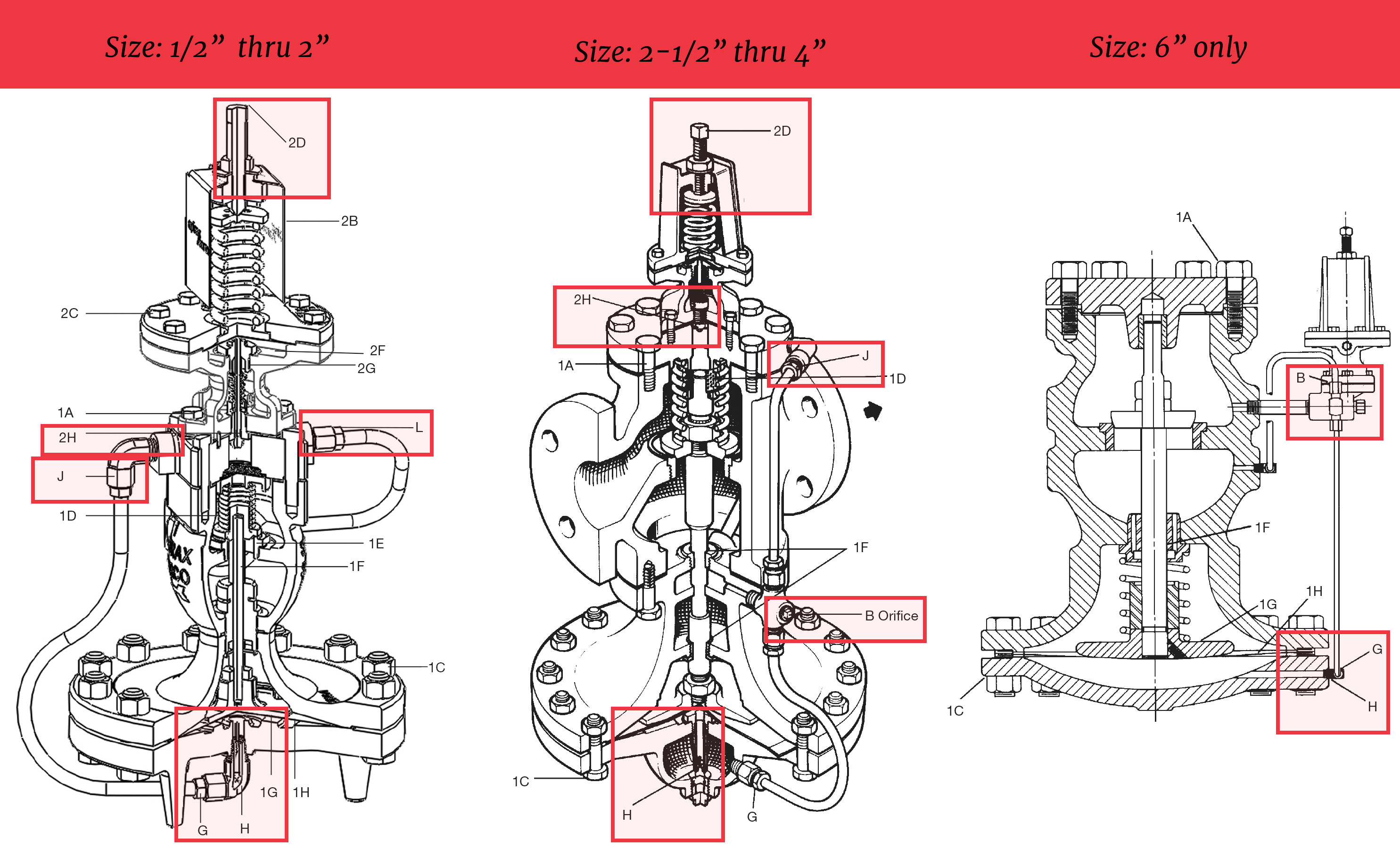

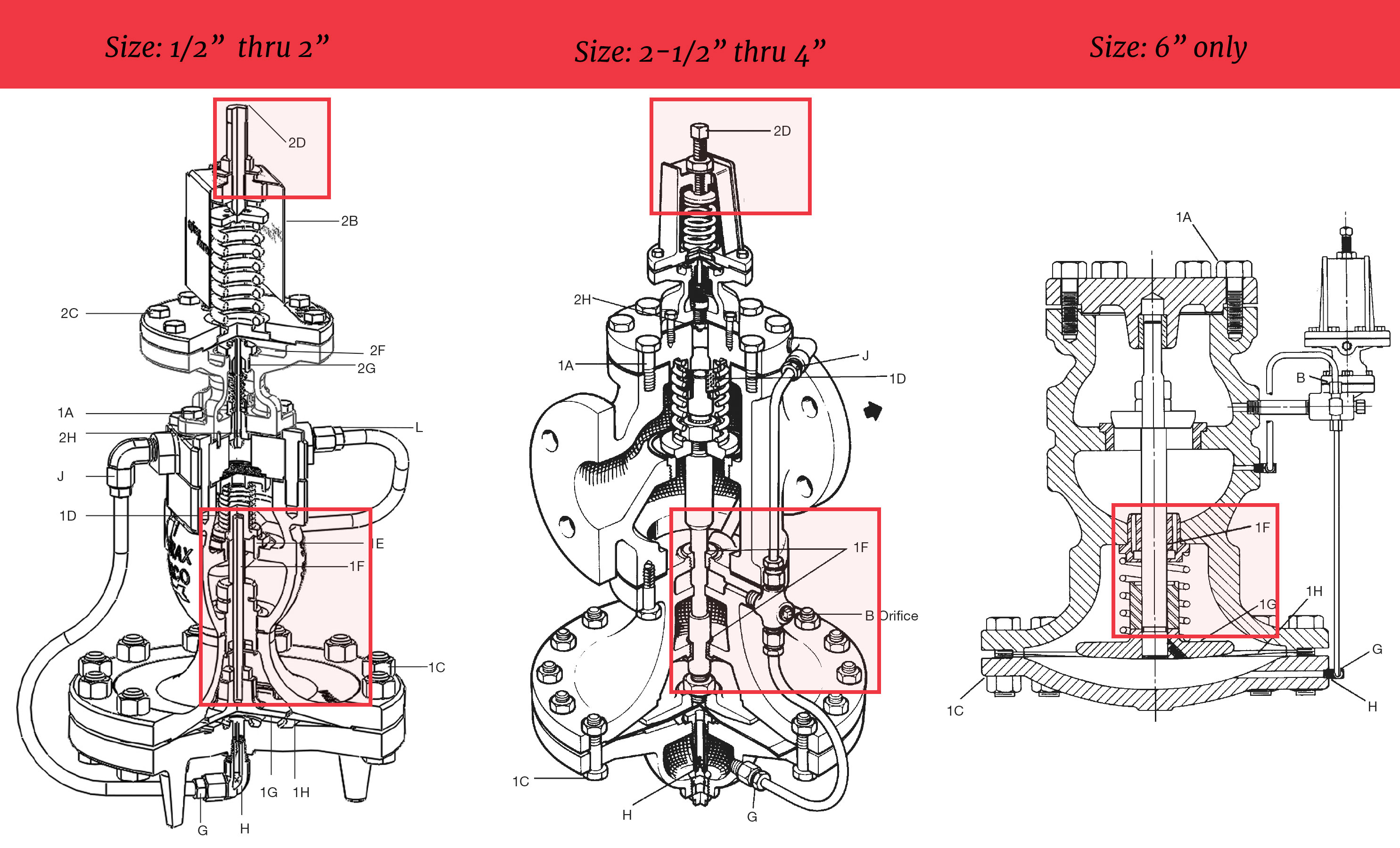

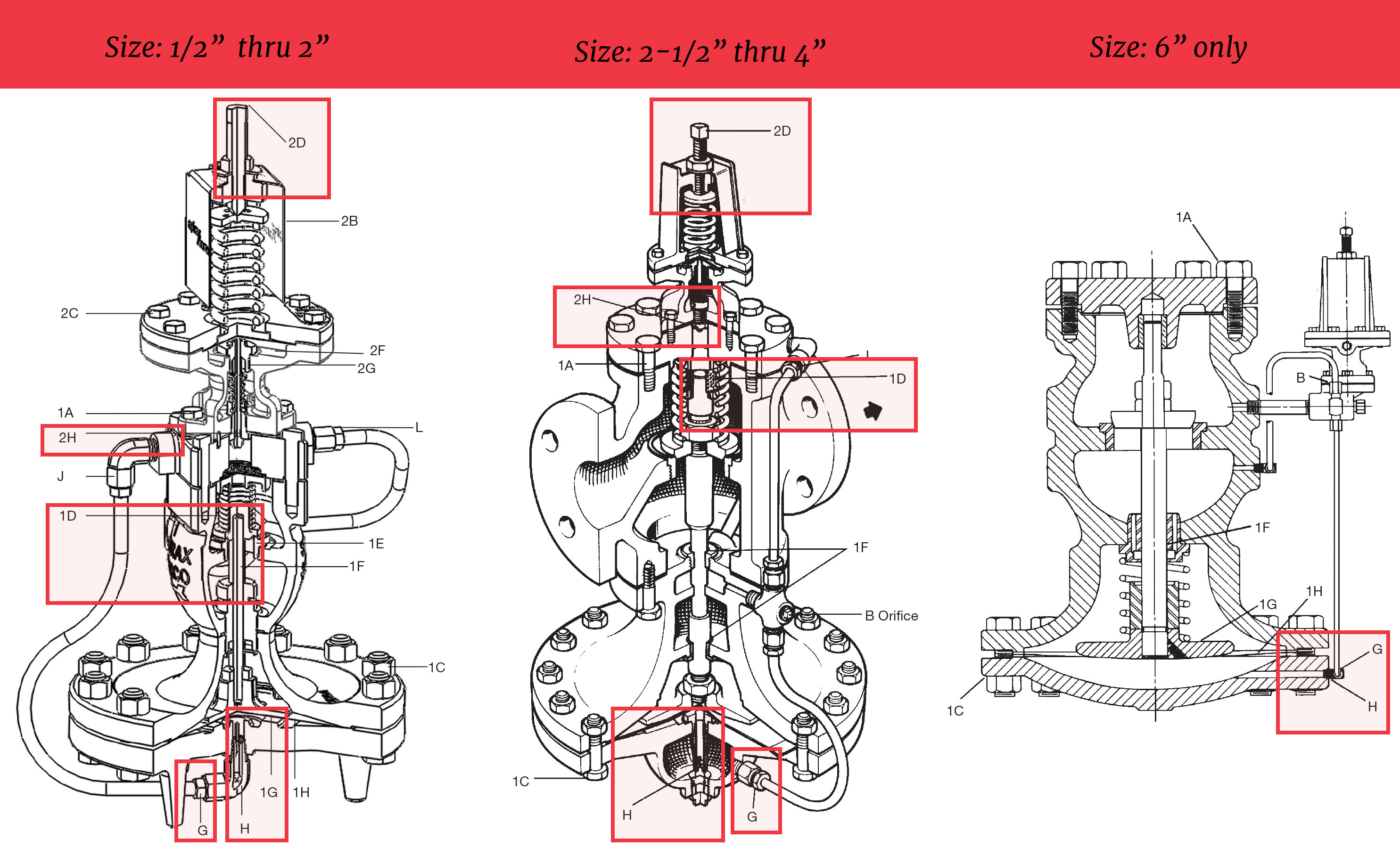

- Dirt or foreign material has gotten in between pilot valve seat and head. To check if this is your cause, first loosen the screw (2D), and then remove the copper tubing connections at (J and L.) With steam on the valve, if the steam flows from the copper tubing connections at J & L, remove the pilot head and seat assembly (2H) and either clean or replace.

- Foreign particles have gotten between the main valve head and seat. Inspect and clean the head and seat.

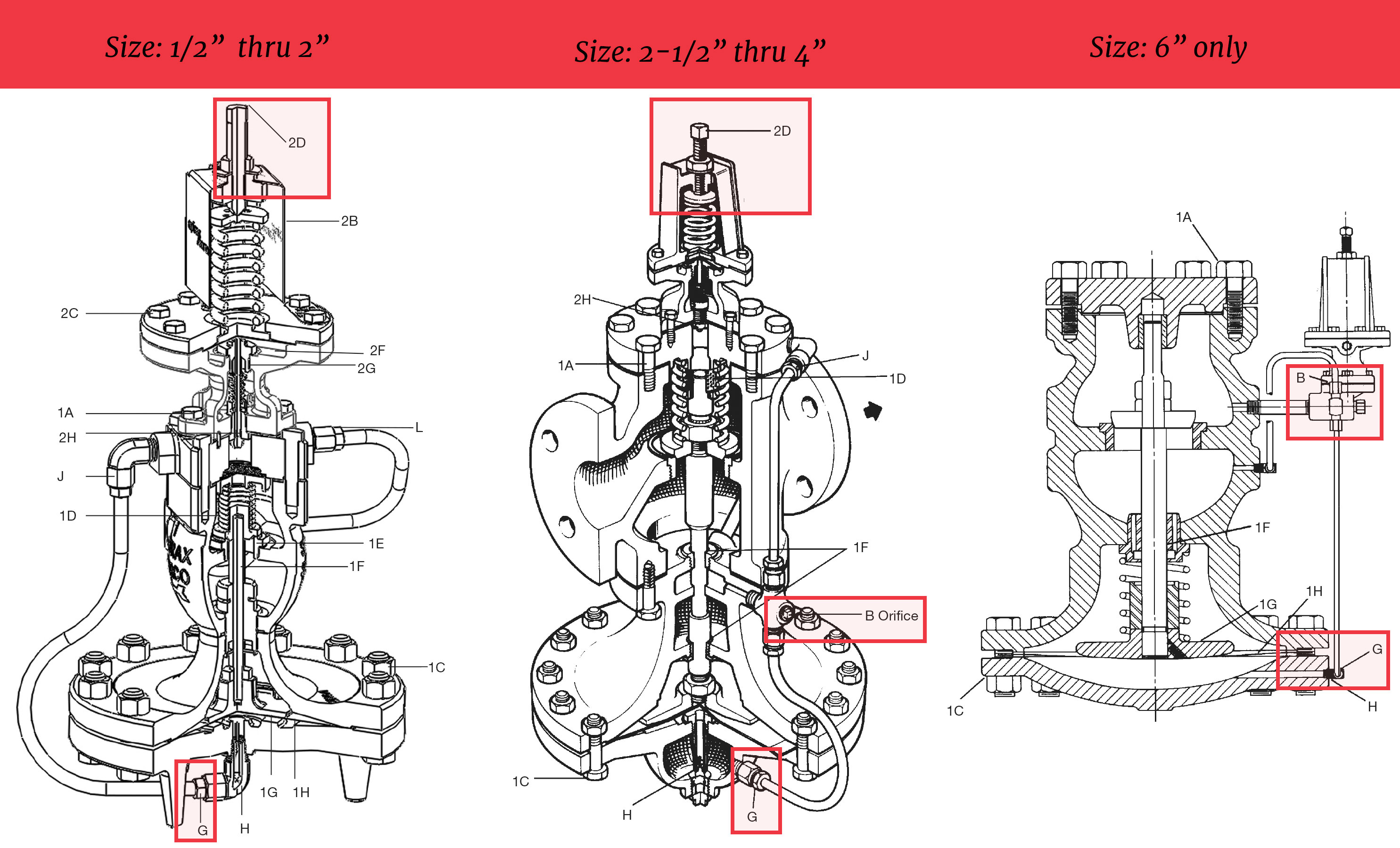

- Orifices (B) and (H) or pressure sensing line may be plugged. Remove, inspect, and clean the orifices and lines.

Steam Pressure Reducing Valve Failure Symptom 2: Controlled pressure overshoots only on light loads.

There are four main causes for your pressure reducing valve to fail by over-shooting under light load conditions:

- The main valve head and seat may be worn or there is dirt between them. Inspect and clean the valve head and seat.

- The valve may be severely over-sized. You can adjust the screw (2D) to give the desired pressure under light loads.

- The bypass valve is not shut tightly or is leaking. Check and repair as required.

- Dirt or foreign material is on the main valve stem and guide (1F). Remove, inspect and clean the parts.

Steam Pressure Reducing Valve Failure Symptom 3: The valve fails to open.

There are six main reasons why the valve may fail to open:

- The main valve is ruptured. Unscrew the copper tubing connection at (G) and crack bypass valve. If steam flows from main valve diaphragm case, the diaphragm is defective and must be replaced.

- The orifice (H) is plugged. Remove and clean.

- The pilot valve seat is plugged with dirt. Remove the head and seat assembly (2H). Inspect and clean or replace.

- The screen (1D) is plugged. Inspect the screen and clean.

- The pipeline strainer is blocked. Inspect and clean.

- The pilot valve adjustment (2D) or air loading pressure is not properly adjusted. Adjust the screw (2D) to desired pressure. Also, check the air supply to PA pilots.

Steam Pressure Reducing Valve Failure Symptom 4: Delivery pressure is low.

There are five main reasons why your delivery pressure is low, causing your pressure reducing valve to fail:

- The pilot valve adjustment (2D) is not properly adjusted. Adjust the screw (2D) to the desired pressure.

- The valve is undersized. Check actual load against valve rating to determine if this is your cause.

- The steam supply pressure is too low. Check the steam supply pressure and correct.

- The main valve diaphragm is ruptured. Unscrew the copper tubing connection (G) and crack the bypass valve. If steam flows from the diaphragm case, the diaphragm is defective and must be replaced.

- The bleed orifice (B) missing. Replace proper fitting.

Steam Pressure Reducing Valve Failure Symptom 5: Valve fails to close.

There are five main causes for the valve failing to close, causing your pressure reducing valve to fail:

- The bypass valve is open or leaking. Check and repair as required.

- The pilot sensing line is blocked (or is not installed). Remove, inspect, clean or install.

- The pilot ruptured, meaning water or steam is coming from the pilot at the spring retainer area. Replace the pilot diaphragm assembly.

- The pilot assembly or main valve seat threads are leaking. Check the casting in the seat area for erosion.

- The main valve diaphragm was reassembled without the return spring, and the main valve cover holding valve head closed (1/2” thru 4” sizes only). With main valve cover installed, loosen all main valve diaphragm bolts (1C) and then re-tighten them.

How to Troubleshoot a Spirax Sarco 25 Series Pressure Reducing Valve Video

Spirax Sarco USA has created a video that may also be helpful with troubleshooting Spirax Sarco 25 Series Pressure Reducing Valves. In the video below, a Senior Applications Engineer with Spirax Sarco, Joe Radle, explains and demonstrates how to determine if the Pilot Valve or the Main Valve, in the Spirax Sarco 25 Series Pressure Reducing Valve, is leaking.

-------------------------------

Cooney Brothers is proud to be a Spirax Sarco authorized distributor. As one of their largest stocking distributors in the US, we carry the 25 Series Pressure Reducing Valves and their spare parts. Use our Spare Parts Selection Guide to determine the correct item for your size and style valve. Please contact us with any questions.