Services

Our experienced staff understands your needs and can creatively solve problems. We often suggest alternative items or customized products to reduce cost or improve delivery.

Case Studies: Over 85 Years of Solving Customer Problems

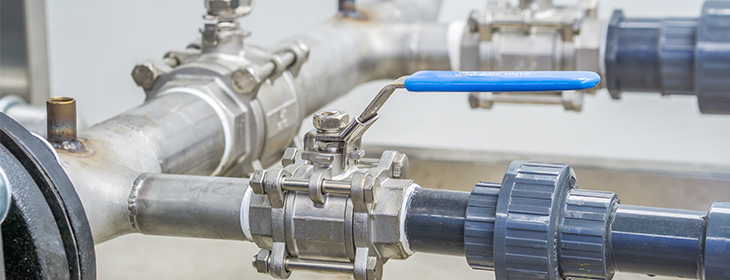

CUSTOM SPACER SOLVES LEAD-TIME PROBLEM

A replacement valve had an unacceptably long lead-time. An alternative was slightly shorter and would not fit between the existing flanges. Cooney developed a custom spacer to fill that gap.

CREATIVE SOLUTION TO SHIPPING PROBLEM

A customer called on Friday afternoon. They needed a 30" pipe cutter for a weekend job. The customer had already spoken to another distributor who told them that the pipe cutter was too heavy (280 lbs) to ship UPS and that it was too late to ship via common carrier. Cooney called the manufacturer and asked if they could disassemble the unit and ship it in 3 cartons. The unit was shipped that way, the customer re-assembled it and finished their work on the weekend.

SAME DAY DELIVERY ON A SUNDAY

Cooney Brothers was contacted on a Sunday morning by a trash-to-steam plant. The plant had experienced failure of a 3" 900# class pressure-seal gate valve. Calls were made to a number of manufacturers and suppliers around the U.S. A suitable valve was located at a specialty supplier in Pittsburgh, PA. A courier was dispatched to pick it up in Pittsburgh and deliver it to Camden, NJ. The valve was installed prior to the start of business on Monday.