Spirax Sarco 1500081 Set of Cover Studs and Nuts for Thermodynamic Steam Trap, Model TD120M & TD120, Sizes 1/2, 3/4, and 1"

CBPN:123865

MPN:1500081

DESCRIPTION

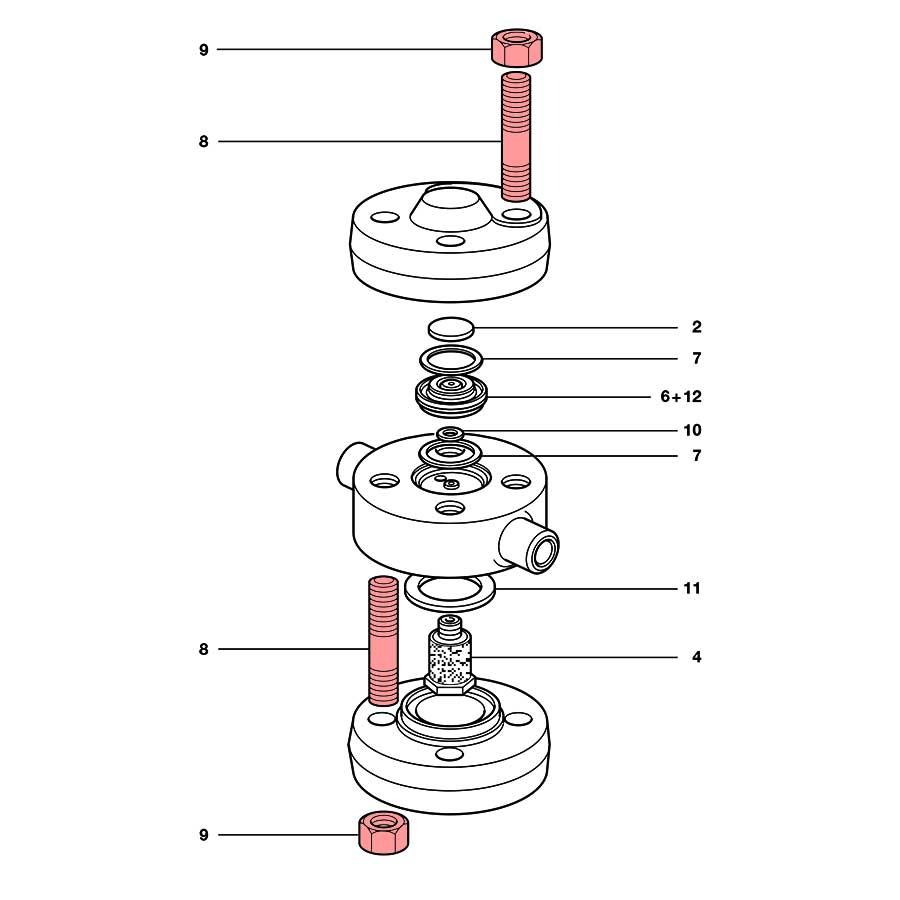

Spirax Sarco Set of Cover Studs and Nuts for Thermodynamic Steam Trap, Model TD120M & TD120, Sizes 1/2, 3/4, and 1"

The TD120M is a maintainable high pressure thermodynamic steam trap with integral strainer and a replaceable seat to ease maintenance, which can be supplied in 1/2 in, 3/4 in and 1 in sizes with socket weld, butt weld or flanged connections. It has low capacity specifically designed for superheated mains drainage applications up to 250 bar g.

Spirax Sarco 1500081 Set of Cover Studs and Nuts for Thermodynamic Steam Trap, Model TD120M & TD120, Sizes 1/2, 3/4, and 1"

CBPN:123865

MPN:1500081

DESCRIPTION

Spirax Sarco Set of Cover Studs and Nuts for Thermodynamic Steam Trap, Model TD120M & TD120, Sizes 1/2, 3/4, and 1"

The TD120M is a maintainable high pressure thermodynamic steam trap with integral strainer and a replaceable seat to ease maintenance, which can be supplied in 1/2 in, 3/4 in and 1 in sizes with socket weld, butt weld or flanged connections. It has low capacity specifically designed for superheated mains drainage applications up to 250 bar g.

Specifications

Item Features

- This product fully complies with the requirements of the European pressure equipment directive 97/23/EC

- Maximum back pressure should not exceed 50% of the inlet pressure under any conditions of operation, otherwise the trap may not shut

- 1160 psig at 1022 deg F Maximum allowable pressure

- 1022 deg F at 0 to 1160 psig Maximum allowable temperature

- 80 mm top to inlet center

- 5437 psig Cold hydraulic test pressure

- 3190 psig at 572 deg F Maximum allowable pressure

- 572 deg F at 3190 psig Maximum operating temperature

- 1022 deg F at 1160 psig Maximum operating temperature

- Maximum operating pressure 3190 psig at saturated steam temperature

- Note: If the product is used at pressures above 170 bar g we would recommend regular inspection of the seat

- Inline horizontal piping configuration