Dixon Sanitary JRZL Series Positive Displacement Pumps

A pump that doesn't have to be removed from the line for maintenance? Yes, that's right. Dixon's JRZL Pumps offer may benefits over other positive displacement pumps, but most impressively:

- Front loading seals allow for maintenance without removing the pump from the line

- Tungsten Carbide/Tungsten Carbide Single Mechanical Seal standard

- Flat front cover, maximizes cleanability of the pump

The Cleanest of Clean, these pumps are 100% CIPable. Small compact lightweight design equals less pump more performance. Gently handle low to high viscosity fluids. Pumps can be fitted with a variety of features and options to ensure the best performance will be achieved for your specific application.

Features:

All wetted parts are 316L stainless steel

Front loading seal options:

- Single(standard)and double mechanical seals, TC vs TC (standard)

- Single and double O-ring seals

- Triple lip seal

- Flush option available on all seal types

Elastomers:

- EPDM (standard), Buna and FKM

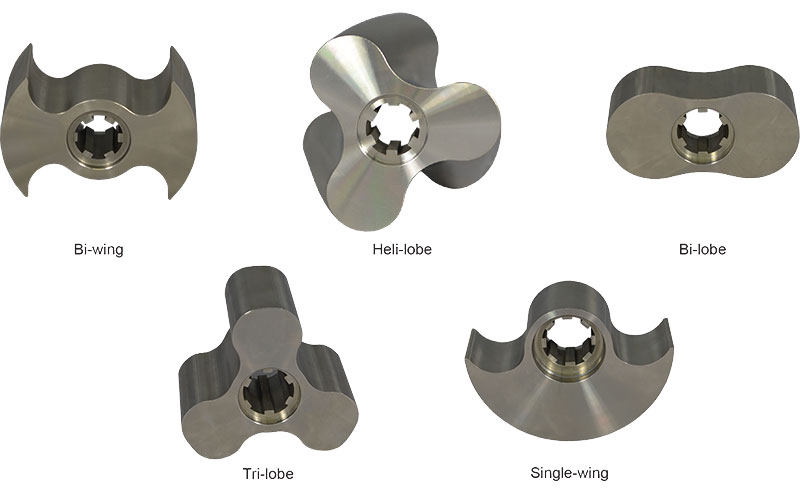

Rotors:

- Bi-Wing (standard)

- Single Wing

- Bi-Lobe

- Tri-Lobe

- Multi-Lobe

- Heli-Lobe

- Hot clearance for temperatures above 248°F

- Viscosity range: 0 - 1,000,000 cP

Connections:

- Clamp (standard), others available upon request

- MODELGal / RevPSIPort SizeJRZL1050.0053001 inJRZL1100.013001 inJRZL1150.031751-1/2 inJRZL1200.061152 inJRZL2200.111752 inJRZL2250.161152-1/2 inJRZL3300.271753 inJRZL3400.381554 inJRZL4400.601754 inJRZL4500.881155 inJRZL2204 in or 6 in4 in10 in

Maximum Speed (RPM)

MODELBI-WINGHELI-LOBEBI-LOBETRI-LOBESINGLE-WINGMULTI-LOBEJRZL105NANANANANA1000JRZL1101000NANANANA1000JRZL115100016008008001001000JRZL1208001600800800100800JRZL2207001400700700100NAJRZL2257001400700700100NAJRZL3306001200600600100NAJRZL3406001200600600100NAJRZL4405001000500500100NAJRZL4505001000500500100NA

Features:

All wetted parts are 316L stainless steel

Front loading seal options:

- Single(standard)and double mechanical seals, TC vs TC (standard)

Elastomers:

- EPDM (standard) and FKM

Rotors:

- Heli-Lobe

Connections:

- FlangedMODELGal / RevPSIPort SizeMAX SPEED RPMJRZL5801.854358 in500JRZL51002.6443510 in500JRZL51203.1743512 in500

Dixon JRZL Pump Benefits

Universal Mounting:

Pumps can be mounted with top/bottom shaft drive, vertical/horizontal inlet/outlet.

Stainless Steel Gear Box

Standard stainless steel gear box with single oil reservoir made from precision casting offers paint free and rust free long lasting durability.

Helical Timing Gears

Using helical timing gears, the rotors are driven at less vibration to extend pump efficiency and seal lifetime, even under high speed and high discharge pressure.

Front Loading Seal

Front loading seals provide faster maintenance, easier cleaning and less down time. All seal options are designed for quick and simple retrofit..

Ease of Shimming

Stainless steel shims being located between gearbox and casing makes it easy to adjust rotor clearance without having to completely disassemble the gear box.

Bi-Wing Rotors

A low-slip Bi-wing rotor maintains efficiency even on low viscosity products by means of longer seal path. Many other rotor options available.

316L Stainless Steel

All product contact areas are standard 316L stainless steel and 25Ra surface finish meets EHEDG and 3A requirements.

100% CIPable

Optimal CIPability is achieved by minimizing the dead-end space between sealed areas.

JRZL PUMP APPLICATIONS

Food Processing:

Sauces, salad dressing, soups, oils, meats, dough, chocolate, candy, etc.

Dairy:

Milk, cheese, ice cream, yogurt, butter, etc.

Beverage:

Juice, water, liquor, specialty drinks, etc.

Pharmaceutical:

Aseptic, metering, R & D, sterile environments, etc.

Personal Care:

Moisturizer, cosmetics, toothpaste, shampoo, etc.

Industrial:

Paint, resin, ink, chemicals, detergents, etc.